Subscribe to the blog

Advantages of investing in a custom chromatography resin for your target molecule

Jan 14, 2025 10:30:00 AM / The Bio-Works Team

When it comes to optimizing and refining your purification processes, nothing can surpass the precision and effectiveness of a custom chromatography resin. It is designed for your specific requirements, enhances performance, and takes you closer to the highest level of efficiency.

A specifically designed resin takes into account your unique sample type, desired resolution, yield, and throughput. You won’t have to compromise or struggle to adjust to all the conditions anymore. Say goodbye to "making do" with a general-purpose resin.

A custom resin provides a golden opportunity for you to streamline your operations, enhance your output, and achieve the best possible results. Let's look into more detail about how a custom resin could revolutionize your work.

What are the advantages of investing in a custom chromatography resin?

Specific to your target molecule

The very definition of a custom resin is, of course, that it is tailored to your specific needs. If you're working with a unique compound or a modified version of a more traditional molecule, you may need to alter your design space at many process stages in order to create a robust overall result. A custom resin could provide better selectivity and specificity for your application, or it may in fact be the only way to achieve the required results.

Efficiency with the best results

Resins vary in properties such as bead size, pore size, and chemical functional groups that affect the efficiency of your chromatography system. For example, a resin with a larger pore size may allow for faster flow rates, but it may provide a different level of resolution than a resin with a smaller pore size. When a resin is customized to your process, it can enable you to achieve your desired results faster or with less material. A custom resin can save both time and resources, which can be especially important in industrial or high-throughput settings.

Improved yield and purity

A custom resin can offer better yield and purity for your specific application. This customization could be especially important for processes that require high purity, such as pharmaceutical manufacturing. A process could also be improved, for example, by introducing a very specific and efficient capture step so that less polishing is needed, which will reduce the cost, as illustrated below.

Achieve scalability

You may have inherited a process from R&D that was developed at a research scale and proved to be difficult to scale up for manufacturing. An alternative resin configuration could solve this.

Cost-effectiveness

While the initial cost of custom resin might be higher, if it provides better performance and produces a higher yield, it could reduce overall costs.

Innovation

Custom resins allow for innovative solutions to complex problems. By working with a chromatography resin manufacturer to develop a custom solution, you could potentially push the boundaries of what's currently possible in your field.

Additional factors to consider before selecting a custom chromatography resin

Chromatography resins are integral to the success of a purification process. They can significantly influence the performance of your chromatography system, the quality of results, and the overall cost-effectiveness of your process. It's, therefore, also critical to ensure that the resin you choose is fully compatible with your system and procedures.

Sample compatibility

Your current resin may not be compatible with the sample being analyzed. Some resins may interact with certain types of molecules in your sample, potentially leading to inaccurate results. If the resin has a high affinity for certain compounds, it might retain them too strongly, making elution difficult. A custom resin will allow you to avoid this problem.

Chemical stability

A resin must be chemically stable under the conditions used in your chromatography system. Some resins may degrade or lose their functionality if exposed to certain chemicals, temperatures, or pH levels. A typical example is cleaning-in-place, which may require the use of NaOH at concentrations that your current resin does not tolerate. Changing to a different resin base matrix (bead material) could solve this.

Regulatory compliance

If you work in a regulated industry (like pharmaceuticals), the resin you use must meet specific regulatory standards. These regulatory standards might include things like being certified free of specific contaminants. An important aspect is the provision of all necessary regulatory documents and GMP certification - for example, for pre-packed columns containing the resin.

Several parameters can be modified to customize a resin

With experience in creating and modifying chromatography resins, it is possible to modify various features of a resin using knowledge of how each can affect the final results.

For example, the agarose-based chromatography resins, called WorkBeads, that Bio-Works produce can be modified in several ways.

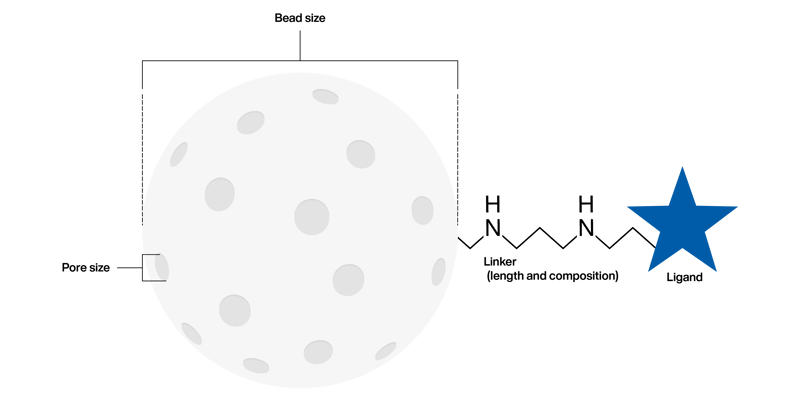

Depending on the area of use, a resin may be composed of the base matrix (the bead), a linker arm, and a ligand.

Each of these can be adjusted in the following ways:

Bead size

- Large – for a capture step (> 65 µm)

- Mid – for an intermediate step (40 ~ 65 µm)

- Small – for a polish step (< 40 µm)

Pore size (Globular protein exclusion limit)

- 100 kDa cut-off

- 1000 kDa cut-off

- 10000 kDa cut-off

- 30000 kDa cut-off

Linker

- Length

- Atomic composition

Ligand

- Nature of ligand

- Concentration of ligand immobilized on bead/base matrix

Changing one or more of these parameters could make the difference between being able to purify a target molecule or not. However, it could also produce an incremental change that suddenly makes a process economically feasible.

This is how you get started

First of all, remember that it's crucial to work closely with a knowledgeable and experienced resin manufacturer when pursuing a custom resin solution. They can help guide you through the process and ensure the final product meets all your needs.

The procedure for developing a custom resin at Bio-Works is an example of what the whole process can entail.

In summary:

Diagram of Bio-Works custom chromatography resin development

Diagram of Bio-Works custom chromatography resin development

Do you have a specific purification challenge that you need help with? Are you curious to know whether a custom resin is the solution? Discover our custom chromatography resin services and how WorkBeads can be custom-made for your purification needs.